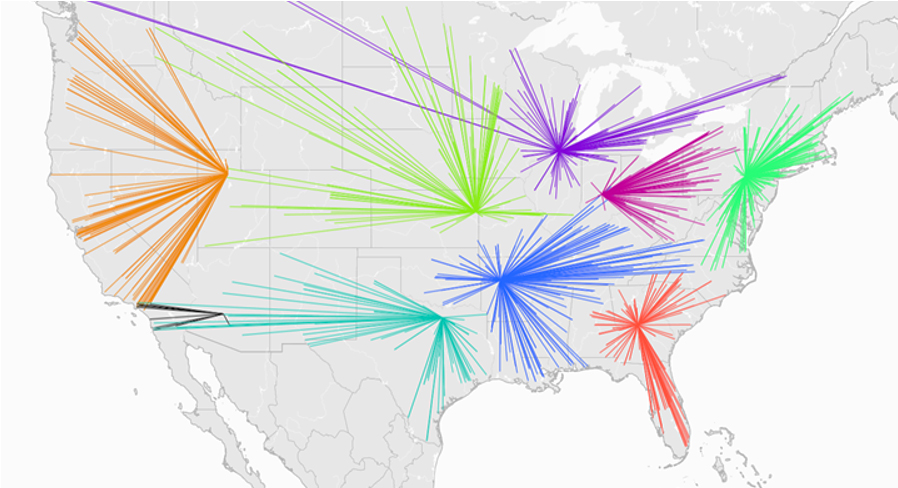

We’re always looking at processes and systems that will make us better as a company, more effective and carry us into the future. In recent years, we’ve evaluated our distribution model to determine a more efficient and cost-effective way of getting various products to our customers.

These discussions around our poultry and prepared foods networks have led to Tyson Foods’ Distribution Network of the Future – the next step in revolutionizing the way we pack and ship products across the U.S.

“We knew there was a better way to serve our customers,” Chief Supply Chain Officer Bernie Adcock said. “Now, we’ll have inventory positioned within a day’s delivery to a majority of our customers.”

Prior to the launch of this initiative, our distribution network was a blend of three separate networks:

- Legacy Tyson (a centralized model with three primary distribution centers)

- Legacy Hillshire (a regional model with five distribution centers)

- Legacy Advanced Pierre Foods (a regional model with three distribution centers)

The Distribution Network of the Future allows us to capitalize on the strengths of the existing networks while driving new efficiencies. These changes will result in reduced mileage, labor, outside cold storage fees and handling charges. What would have previously been a four or five-day haul will now only take about a day or two to reach the customer.

Fully implementing our Distribution Network of the Future will take some time. But changes are already under way.

Last year, we moved refrigerated Legacy Tyson volume into our Macon, Georgia, and Pottsville, Pennsylvania, facilities. Shortly after, we opened a facility in the Indianapolis, Indiana, area where we are now shipping a combination of Legacy Hillshire and Legacy Tyson items.

“Over the last 30 years, we’ve grown the business, and now we’re refining our distribution network design to support that business while also preparing for future growth,” Director of Network Strategy Jason Nixon said. “The key concept behind this project is pulling our product portfolios together to maximize our efficiencies.”

This month, we introduced frozen poultry products in our Rochelle, Illinois, distribution center. And in the year ahead, we’ll reposition inventory into our Macon and Pottsville distribution centers and open a facility in Fort Worth, Texas.

Each of these changes bring us one step closer to being able to ship items from our entire frozen poultry and prepared portfolio on a single truck.

“We asked ourselves where we could innovate,” Senior Vice President of Distribution Kyle Neely explains. “Shipping direct from the production plant is the most efficient distribution path, and we won’t change that design.”

Karen Schmarje, senior manager, Network Strategy, says our customers have a lot to gain from the rollout of this plan.

“This initiative has been a lot of hard work over the course of several years so it’s great to see it finally come to life.”